WHY is BoMill InSight™ different from optical sorters?

In today’s grain processing landscape, optimizing resources, and achieving optimum quality standards are paramount. Up to recent years, optical sorting technologies have been at the forefront of grain cleaning and quality control. But today, BoMill offers a new dimension to grain sorting.

Let’s explore both technologies, their applications and differences in grain quality enhancement.

Optical sorters identify visual defects

Using advanced cameras and sensors, an optical sorter, also called color sorter, examines materials as they fall through the equipment. It analyzes external features like color, size, shape, and texture to eject items based on preset criteria.

Product purity is thus improved by removing non-conforming kernels and foreign materials.

BoMill InSight™ Looks inside each kernel

Using Near-Infrared (NIR) light in transmission mode, BoMill InSight™ assesses and separates batches based on inner qualities like protein content or fusarium contamination.

By leveraging quality differences within grain lots, BoMill InSight™ enables processors to extract premium fractions or recover grain that would otherwise go to feed or waste, adding value and sustainability benefits.

Comparison

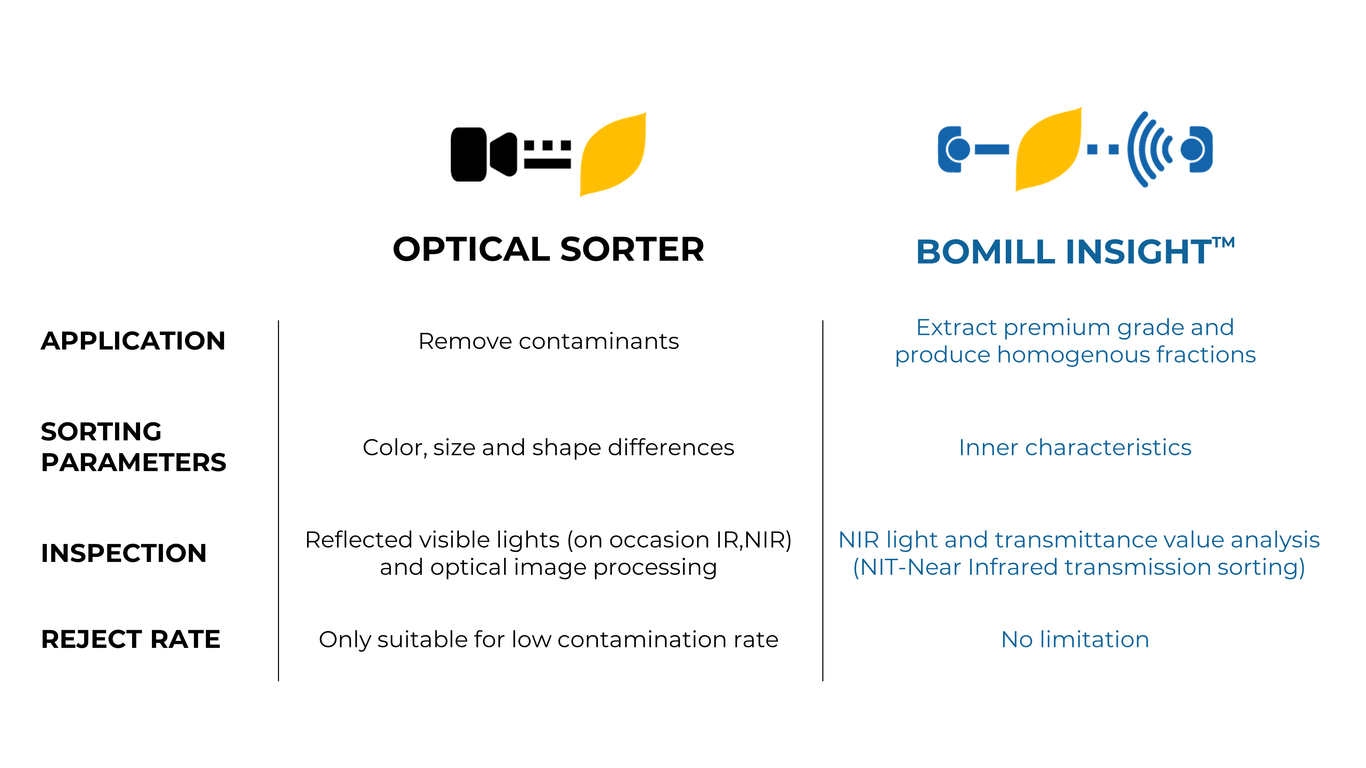

Both technologies aim to enhance grain quality but vary significantly in their methods and applications.

Optical sorting excels in rapid surface-level inspection, using reflected light evaluated through image processing. It is ideal for removing small amounts of impurities and contaminants but cannot sort based on inner properties

In contrast, the BoMill technology analyzes the NIR signal passing through each kernel, offering a deeper analysis of internal characteristics. The batch separation can therefore be done, based on inner parameters like protein content with no limitation for the size of the ejected fraction.

Conclusion

In the grain processing landscape, BoMill InSight™ redefines grain sorting beyond the capabilities of traditional optical sorters. The unique ability of BoMill InSight™ to separate a batch based on the protein content for each single kernel, sets it apart as a forerunner in the pursuit of superior grain quality. This innovative approach not only enhances grain quality but also adds significant value, particularly in industries like flour milling or malting, where uniformity and specific functional properties are crucial.