BoMILL InSight

The next generation of grain quality sorting

BoMill InSight™ is the only grain sorting equipment able to process grain lots, kernel by kernel, at industrial speed, based on on each single kernel’s inner properties

BoMill InSight™ looks inside every kernel in a batch of grains to accurately sort into two quality fractions. This is done using our proven sorting technology, based on Near-Infrared Transmission (NIR-T) spectroscopy,

With a flexible sorting capacity from 2 and up to 120 mt/h, our system addresses the sorting needs of all types of grain processors where inner properties, such as protein content, are of interest for process and supply chain optimization.

Wheat

Barley

VERSATILE

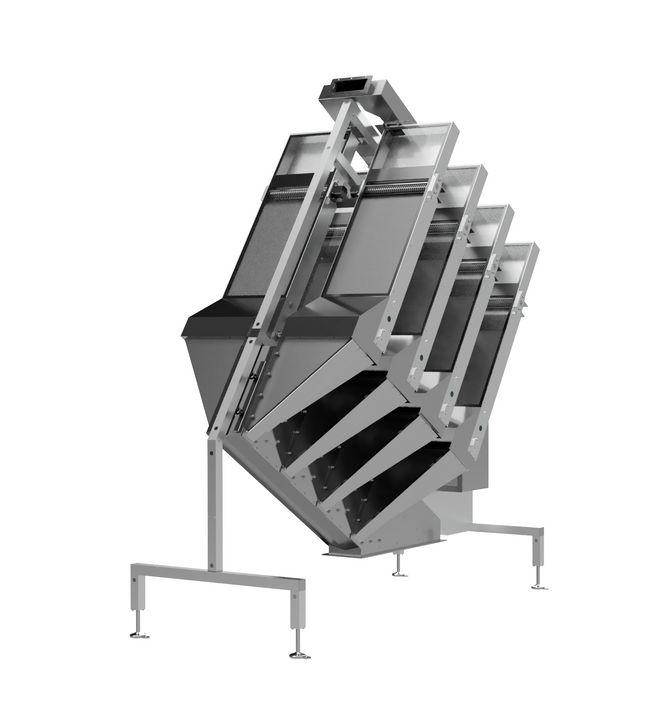

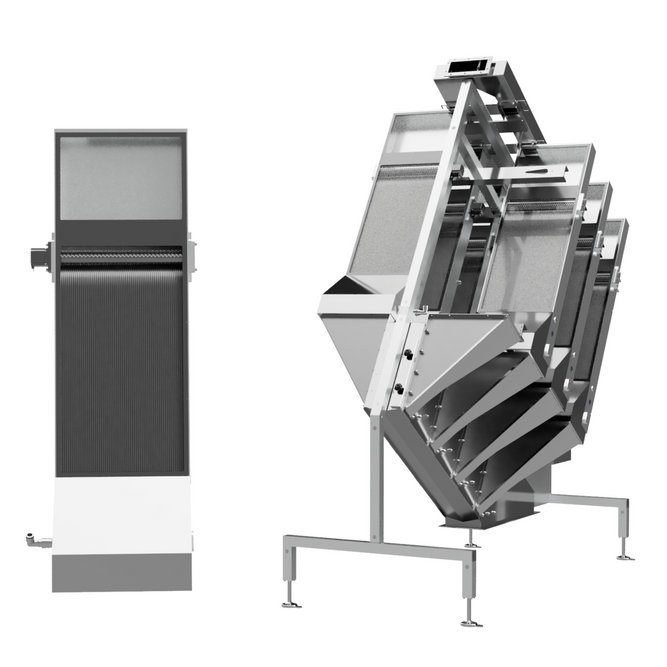

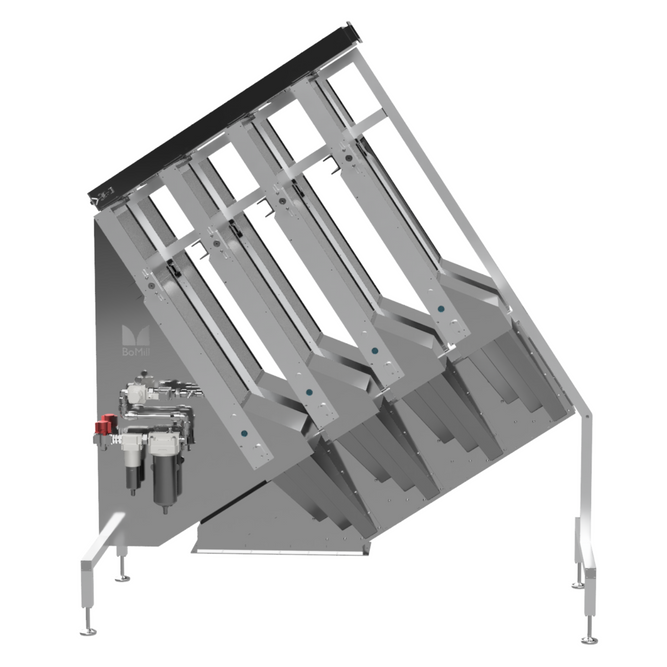

The revolutionary modular design of BoMill InSight™ consisting of a frame fitting one to eight sorting units, offers maximum flexibility for operations and easy upgradability

COMPACT

BoMill InSight™'s smart frame design and compact footprint allow easy and rapid installation in new or existing grain processing lines

Cost-effective

BoMill InSight™ offers cost-effective installation, operation, maintenance and upgradability. Its low total cost of ownership allows a fast return on Investment.

EASY TO USE

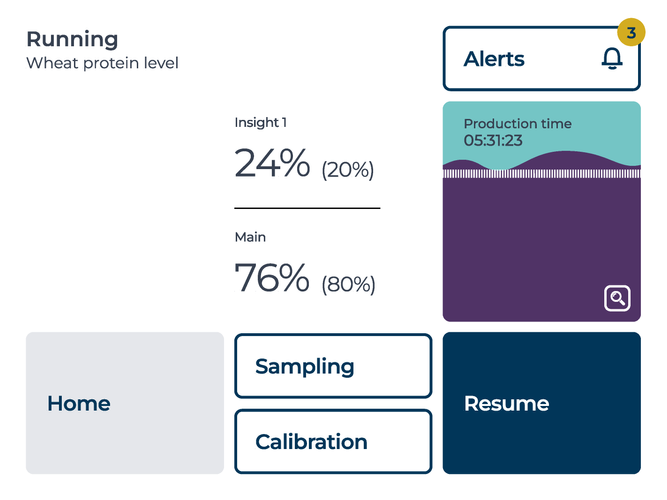

BoMill InSight™ is easily operated using its user-friendly interface.

After initial sampling of the material to assess its quality variation, all you need to do is select the yield for the two fractions to be generated. The intelligent sorting is then carried out automatically.

upgradability to suit your needs

As your business evolves, you can easily increase capacity by simply adding an extra sorting units to the frame of BoMill InSight™.

Multiple frames can also be clustered for even greater processing power.

ExampleS of installation

Container installation in a grain terminal (Sweden)

For a fast and simple deployment, BoMill InSight™ can be supplied as a built-in plug & play mobile unit with a configuration to suit your needs (e.g. supply of compressor).

In this example, BoMill InSight can run up to 15tons/h (equivalent to 125 000 kernels analyzed per second) to upgrade milling wheat and malting barley, based on protein content. The container is installed in the intake building of the grain terminal.

Mobile trailer (Denmark)

Visti Møller, owner of Gl. Buurholt, the largest mobile seed processing company in Scandinavia, and Jon Aagaard Enni from the Danish Innovation Centre for Organic Farming describe how BoMill InSight™ enhances grain quality with its ability to sort on protein. In this example, the solution is installed on a mobile trailer.

Video produced by the Danish Innovation Centre for Organic Farming