Making every grain count

THERE IS MORE TO YOUR GRAIN

You have the potential to add value to your grain while optimizing supply and improving process efficiency. Exploit the quality variation within your grain lots. Sort accurately each individual kernels, based on their inner properties

MANAGE PROTEIN LEVEL

REMOVE FUSARIUM

OPTIMIZE GRAIN SUPPLY

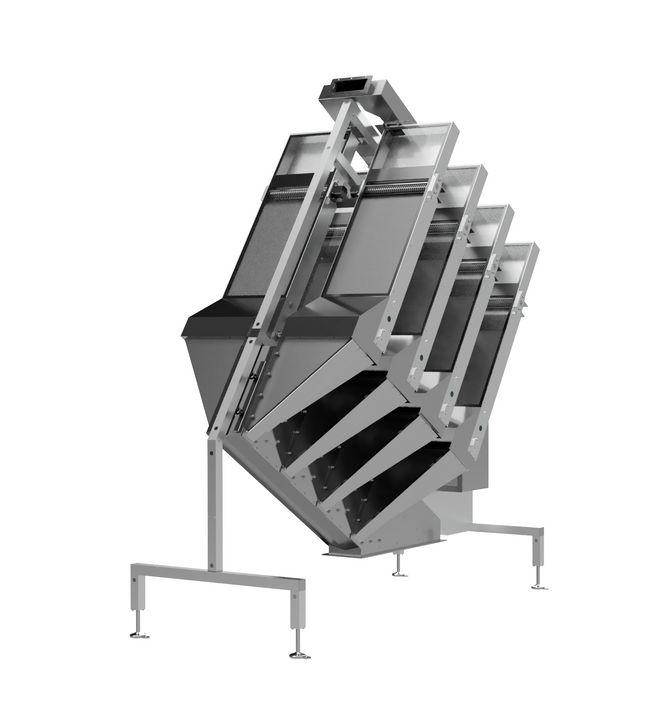

Revolutionary design & Unique performance

Latest news and releases

BoMill publishes prospectus regarding the Rights Issue

23 April 2024

THIS PRESS RELEASE IS NOT FOR RELEASE, DISTRIBUTION OR PUBLICATION, DIRECTLY OR INDIRECTLY, WITHIN OR INTO AUSTRALIA, BELARUS, CANADA, HONG KONG, JAPAN, NEW ZEALAND, RUSSIA, SINGAPORE, SOUTH AFRICA, SOUTH KOREA, SWITZERLAND, OR THE UNITED STATES OF AMERICA, OR ANY OTHER JURISDICTION IN WHICH THE RELEASE, DISTRIBUTION OR PUBLICATION WOULD BE UNLAWFUL OR WOULD REQUIRE REGISTRATION OR OTHER ACTIONS. PLEASE REFER TO THE SECTION “IMPORTANT INFORMATION” BELOW.

Today, BoMill AB (the “Company” or “BoMill”) has published a prospectus (“Prospectus”) regarding the forthcoming rights issue of shares with preferential rights for existing shareholders (the “Rights Issue”) resolved by the ordinary general meeting on April 12, 2024. The Rights Issue amounts to approximately a maximum of SEK 16.8 million.

Last day for trading in BoMill's shares including the right to participate in the share issue

17 April 2024

THIS PRESS RELEASE IS NOT FOR RELEASE, DISTRIBUTION OR PUBLICATION, DIRECTLY OR INDIRECTLY, WITHIN OR INTO AUSTRALIA, BELARUS, CANADA, HONG KONG, JAPAN, NEW ZEALAND, RUSSIA, SINGAPORE, SOUTH AFRICA, SOUTH KOREA, SWITZERLAND, OR THE UNITED STATES OF AMERICA, OR ANY OTHER JURISDICTION IN WHICH THE RELEASE, DISTRIBUTION OR PUBLICATION WOULD BE UNLAWFUL OR WOULD REQUIRE REGISTRATION OR OTHER ACTIONS. PLEASE REFER TO THE SECTION “IMPORTANT INFORMATION” BELOW.

Today, Wednesday April 17, 2024, is the last day of trading in shares of BoMill AB (the “Company”) including the right to obtain subscription rights.

Tomorrow, Thursday April 18, 2024, is the first day of trading in Company’s shares excluding the right to obtain subscription rights.

Communiqué from Annual General Meeting in BoMill AB

12 April 2024

THIS PRESS RELEASE IS NOT FOR RELEASE, DISTRIBUTION OR PUBLICATION, DIRECTLY OR INDIRECTLY, WITHIN OR INTO AUSTRALIA, BELARUS, CANADA, HONG KONG, JAPAN, NEW ZEALAND, RUSSIA, SINGAPORE, SOUTH AFRICA, SOUTH KOREA, SWITZERLAND, OR THE UNITED STATES OF AMERICA, OR ANY OTHER JURISDICTION IN WHICH THE RELEASE, DISTRIBUTION OR PUBLICATION WOULD BE UNLAWFUL OR WOULD REQUIRE REGISTRATION OR OTHER ACTIONS. PLEASE REFER TO THE SECTION “IMPORTANT INFORMATION” BELOW.

Latest Report

BoMill Q1 Report January – March 2024

12 April 2024